Laminate/Bakelite

What is Bakelite?

High Pressure Laminate (HPL), also known as Bakelite or polyoxybenzylmethylenglycolanhydride, is a synthetic resin. Bakelite, recognized as one of the first plastics made from synthetic materials, remains a top choice for kitchen furniture, offering durability and elegance. Its exceptional properties make it an ideal option for both homeowners and interior designers.

Historical Background and Invention of HPL

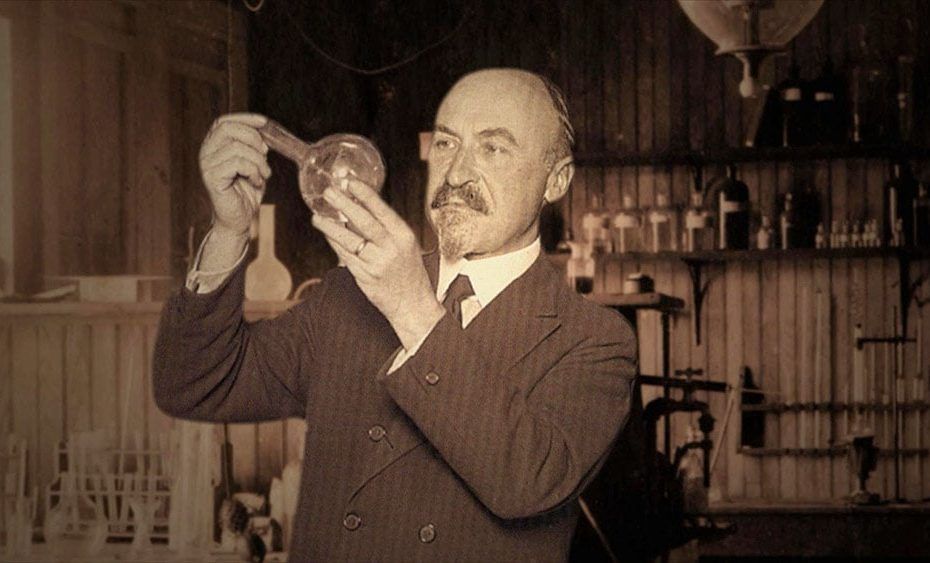

Bakelite, one of the earliest synthetic plastics, was invented in 1907 by Belgian chemist Leo Baekeland in New York. This invention revolutionized the industry due to Bakelite’s durability and excellent insulating properties, making it ideal for electrical components and industrial tools. Baekeland used phenol and formaldehyde to create a thermosetting plastic that could be molded into various shapes and applications. This innovation ushered in a new era of plastic materials, dramatically impacting technology and daily life.

Properties of Bakelite

Bakelite, also known as polyoxybenzylmethylenglycolanhydride, is a thermosetting plastic created from the reaction of phenol with formaldehyde in the presence of catalysts. This chemical reaction creates macromolecules that bond to form a network that doesn’t melt or soften when heated. This structure gives Bakelite its remarkable properties.

The primary properties of Bakelite include:

- Heat Resistance: Bakelite is highly resistant to high temperatures, making it ideal for applications requiring thermal resistance.

- Insulating Properties: It has excellent electrical insulating properties, hence widely used in electrical components.

- Chemical Resistance: It is resistant to many chemical agents, making it suitable for industrial applications.

- Dimensional Stability: It doesn’t easily deform under pressure or temperature, maintaining its shape and dimensions.

Bakelite’s unique characteristics come from its chemical structure—a three-dimensional network of phenolic molecules connected through methyleneglycolanhydride bonds.

General Applications

Bakelite has a wide range of applications thanks to its unique properties, such as heat resistance, excellent insulation, and chemical durability. Here are some of the primary applications of Bakelite:

- Electrical and Electronic Components: Bakelite is extensively used in manufacturing electrical parts due to its excellent electrical insulating properties. Applications include switches, sockets, plugs, and other components where insulation is crucial.

- Industrial Tools and Equipment: Its heat and chemical resistance make Bakelite ideal for use in industrial tools and equipment. It’s used in machine parts and other industrial applications where durability is essential.

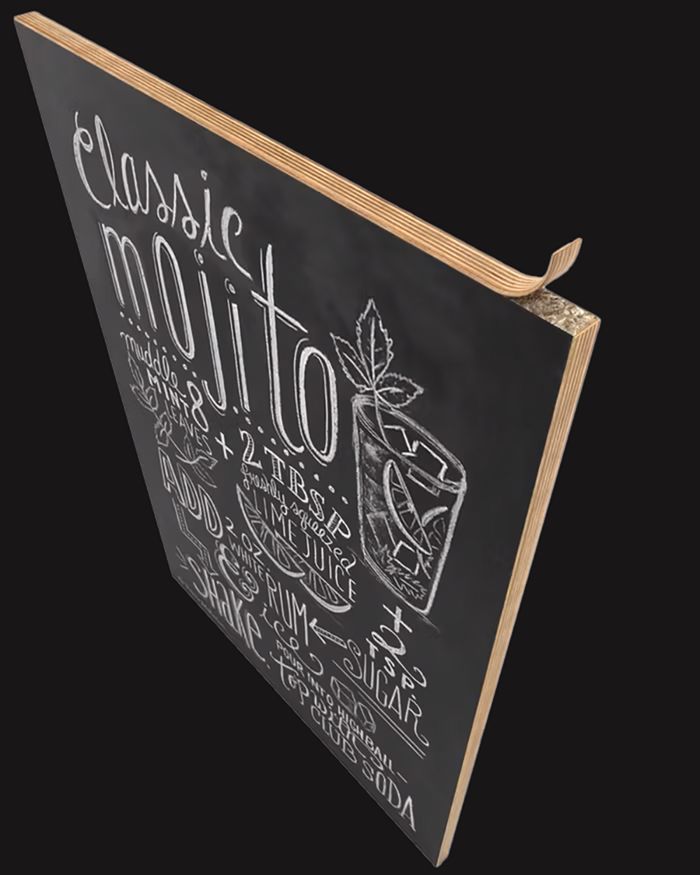

- Furniture and Decor: In the furniture industry, Bakelite is used to create durable and aesthetically pleasing surfaces. Applications include kitchen countertops, cabinet doors, and backsplashes, where both durability and elegance are essential.

- Consumer Products: Bakelite has historically been used to make various consumer products like telephones, radios, and buttons due to its strength and ability to be molded into various shapes and colors.

- Automotive Industry: It’s used in various car parts, such as switch covers and engine components, due to its thermal resistance and insulating properties.

Applications in Kitchen Furniture

When combined with MDF or particle board and phenolic resin, Bakelite offers a broad range of colors and designs. This composition creates durable and visually appealing surfaces, ideal for numerous applications in furniture and decor. Common applications of Bakelite in kitchens include countertops, cabinet doors, and backsplashes.

Why Choose Bakelite for Kitchens?

Bakelite has become a top choice for kitchen furniture, blending durability with aesthetics. Its unique properties make it a preferred option for both homeowners and designers.

Choosing Bakelite for kitchens offers many advantages, such as cost-effectiveness, easy maintenance, and a wide range of design options.

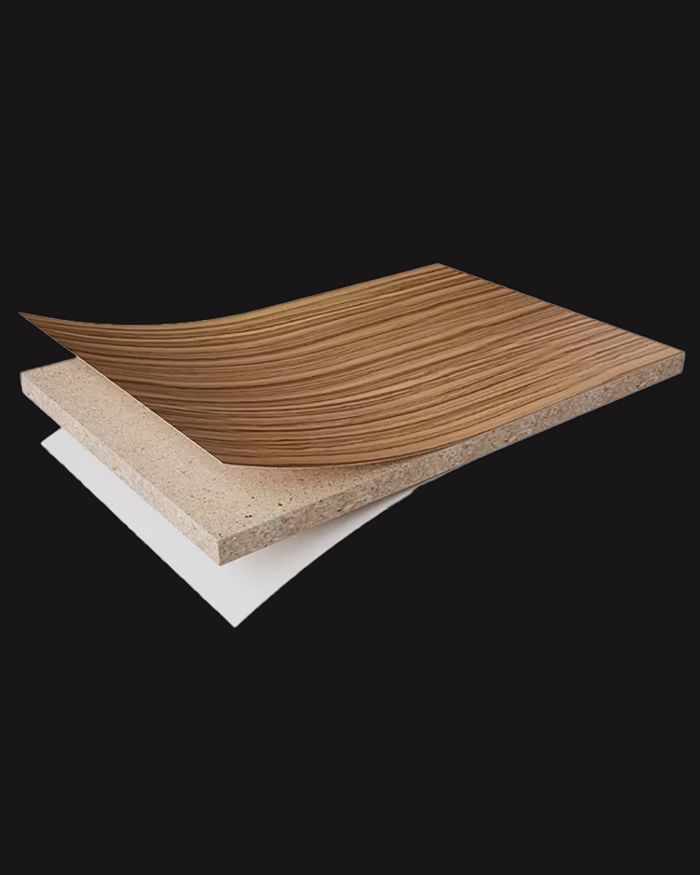

Standard Characteristics of HPL Bakelite Sheets

Standard HPL Bakelite sheets for worktops have a thickness of around 0.7 mm and are securely bonded to particle board, ensuring a combination of style and substance for interior spaces.

Maintenance of Bakelite Surfaces

Maintaining Bakelite is straightforward. Regular cleaning with mild detergents and prompt repair of minor damage can significantly extend its lifespan.

Environmental Impact

The production of Bakelite involves sustainable practices and is recyclable, making it an environmentally friendly choice for kitchen furniture.

Bakelite’s production and use have both positive and negative environmental impacts, depending on the practices followed in production and recycling.

Positive Impacts

- Durability and Longevity: Bakelite is very durable and long-lasting, reducing the need for frequent replacements and thus lessening the environmental impact of producing new materials.

- Recycling: Bakelite can be recycled in certain cases, reducing waste and supporting a circular economy. Modern manufacturing methods focus on using recyclable materials and sustainable practices.

Negative Impacts

- Production and Energy Consumption: Producing Bakelite requires energy and chemicals such as phenol and formaldehyde, which can harm the environment if not managed correctly.

- Gas Emissions: The production process can emit harmful gases and waste, which, if uncontrolled, can contribute to air and water pollution.

- Waste Management: If not properly recycled, Bakelite can end up in landfills, where its decomposition may create environmental issues due to its chemical components.

Environmental Certifications and Sustainability

Many modern companies producing Bakelite or similar materials aim to acquire environmental certifications, such as:

- ISO 14001: Certification for environmental management systems.

- LEED: Certification for green buildings using sustainable materials.

- Greenguard: Certification for products with low chemical emissions.

- Forest Stewardship Council (FSC): Certification for wood elements sourced from sustainable sources.

Comparison with Other Materials

Bakelite is a popular choice in kitchen construction due to its cost-effectiveness, ease of maintenance, and design flexibility, standing out compared to traditional materials like solid wood, granite, and quartz.

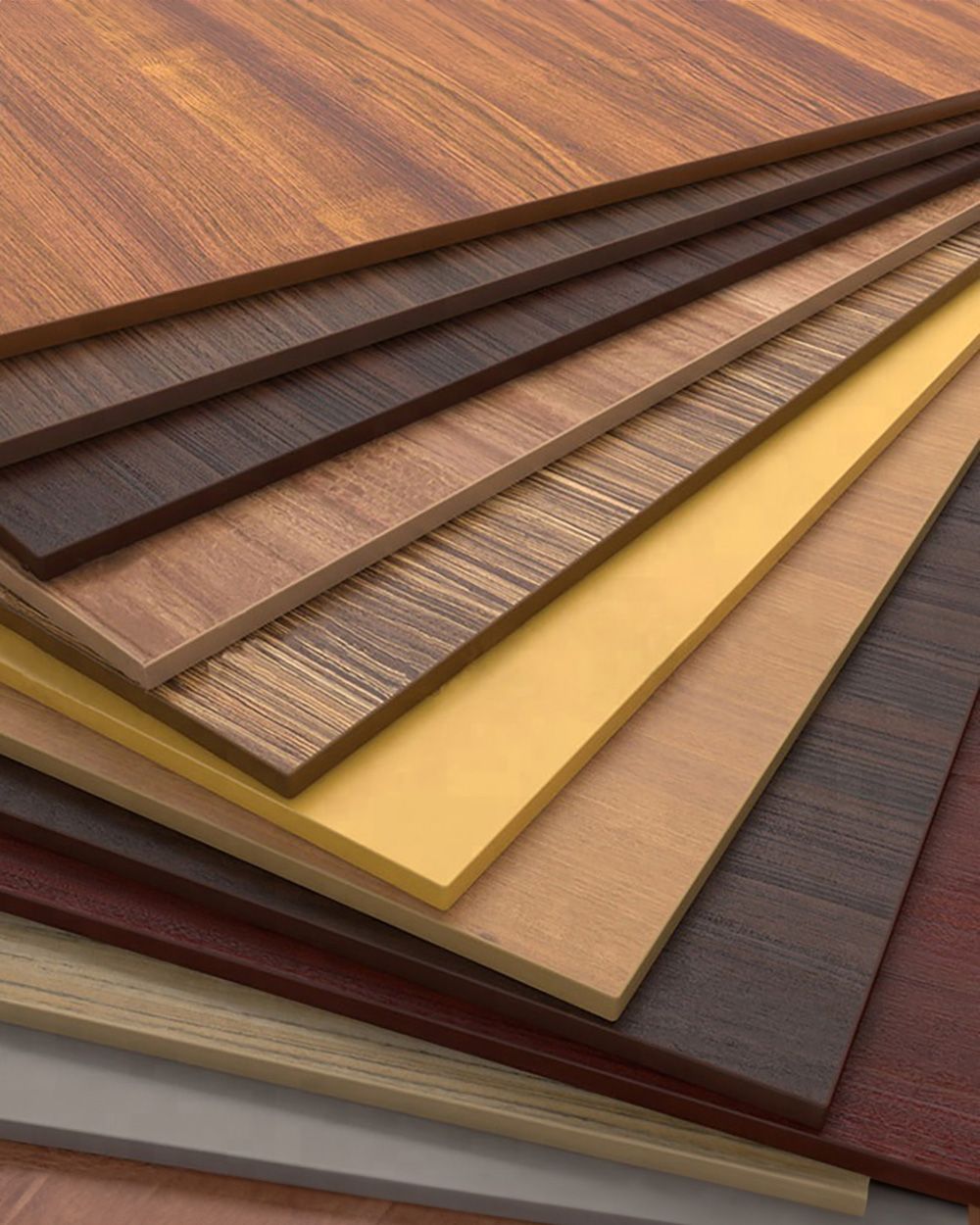

Design Options

Bakelite offers a wealth of design options, including various colors, textures, and patterns, with customization available to match specific aesthetic preferences.

Common Issues and Solutions

While durable, Bakelite can face issues like scratches, heat damage, and stains from harsh liquids. Some of these can be resolved with proper care and maintenance techniques.

Innovations in Bakelite Laminate

Recent innovations in Bakelite Laminate have enhanced its durability and design flexibility, making it an even more attractive choice for modern kitchens.

FAQs on Bakelite Laminate

- What is Bakelite and what is it used for? Bakelite is used to manufacture a variety of products, including kitchen countertops, electrical insulators, and early plastic items.

- How do I clean Bakelite surfaces? Clean Bakelite surfaces with mild soap and water, avoiding abrasive cleaners.

- Is Bakelite environmentally friendly? Yes, modern manufacturing ensures that Bakelite is recyclable and sustainably produced.

- Can Bakelite be repaired? Minor damage on Bakelite surfaces can be repaired with specialized kits available on the market.

- What are the disadvantages of Bakelite? Bakelite may crack under extreme pressure and may not withstand prolonged exposure to harsh chemicals.

- How does Bakelite compare to other materials? Bakelite is more affordable and easier to maintain than many other materials, offering excellent durability and aesthetic appeal.

Why is Kitchen Laminate Referred to as Bakelite in Greece?

In Greece, the term "Bakelite" is often used to describe laminate countertops, even though true Bakelite is a different material. This usage can be attributed to several reasons:

- Historical Significance: Bakelite was one of the first widely used plastic materials and was very popular in the furniture and decoration industry. The term Bakelite became synonymous with durable plastic materials for many generations.

- Similar Properties: Although laminate and Bakelite are different materials, they share some similar properties, such as durability and ease of cleaning. This has led to the use of "Bakelite" to describe laminate in kitchen countertops.

- Commercial Terminology: Commercial and manufacturing terms are often adopted based on common understanding rather than technical accuracy. Thus, "Bakelite" may be used by manufacturers and sellers to describe laminate countertops because the term is familiar and understandable to consumers.

- Popular Usage: Consumers often use terms they have heard and understand, even if they are not technically precise. Using "Bakelite" for laminate may have become established in common language as a more recognizable description.

While the term "Bakelite" is technically inaccurate for describing laminate countertops, it has become widely accepted in everyday language and commercial transactions in Greece.

Conclusion

Bakelite Laminate is a practical and stylish choice for kitchen furniture. Its benefits, such as durability, cost-effectiveness, and easy maintenance, make it an ideal choice for homeowners looking to enhance their kitchen spaces.

It is recommended for use in:

- Kitchen furniture

- Bedroom wardrobes

- Bathroom furniture

- Living room furniture construction

Comparison Between HPL Bakelite and Melamine

Understanding the difference between melamine and Bakelite in kitchen furniture is essential. The term "Bakelite" often refers to HPL, which is much more durable than standard melamine. Furniture marketed as Bakelite but not made from HPL may not provide the expected durability and quality. True Bakelite furniture stands out for its resistance to wear, heat, and chemicals, while melamine offers a more affordable but quality solution.

Bakelite:

- Composition: Bakelite is a thermosetting plastic made from phenol and formaldehyde. It was discovered by Leo Baekeland in 1907.

- Properties: Bakelite is highly resistant to heat and chemicals, with excellent electrical insulating properties.

- Uses: Primarily used in electrical components, industrial tools, and other applications where durability and insulation are crucial.

Melamine:

- Composition: Melamine is an aminoplastic, usually made from melamine-formaldehyde resin. It is a thermosetting material.

- Properties: Resistant to scratches, impacts, and chemicals. It is often used as a surface on wooden substrates for furniture manufacturing.

- Uses: Primarily used for creating furniture surfaces, such as kitchen cabinets, tables, and shelves, as well as work surfaces.

- Durability: Melamine offers a wide range of colors and designs, allowing for customization to personal taste, while its scratch resistance ensures long-lasting functionality and aesthetic integrity.

Differences:

- Chemical Composition: Bakelite is a phenolic resin, whereas melamine is an aminoplastic resin.

- Uses and Applications: Bakelite is mainly used to make durable and insulating materials in industrial and electrical products. Melamine is mainly used for decorative and protective furniture surfaces.

- Properties: Bakelite has excellent heat and chemical resistance, while melamine is scratch-resistant and easy to clean.

Can Melamine Be Called Bakelite?

Melamine and Bakelite are two different materials, and it is incorrect to call melamine Bakelite. Although both are thermosetting plastics, they have different chemical compositions, properties, and uses.